Cutting new fiberglass for the tops of the rudders (again...)

102 Spray Bimini

Summary: A productive week, as we had lots going on and a good team. Accomplishments this week include:

|

Cutting new fiberglass for the tops of the rudders (again...) |

Monday, October 14:

A whirlwind beginning to the week with lots of things going on.

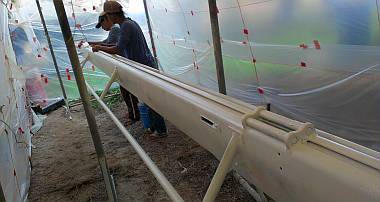

Baw's first concern was getting the forebeam painted with its topcoat. Pla worked with Heru in the morning to build a new plastic tent for the forebeam before its spray. Too bad they didn't do that a couple days ago, then they could have done all the sanding and preparation without plastic around them.

While the new tent was going up, Baw was asking about whether or not we were going to tint the white Interthane 990 to match Ocelot White. If we don't tint it, it will be easy to match the paint later, if we want to touch up any of the spars. But having everything the same color would look very ... finished. Sue's take on it was that we should only consider tinting the Interthane if it was done by (repeatable) computer tinting. Baw might be good with color matching by eye, but there was no way to guarantee a match on all the spars in multiple cans of paint.

Baw spraying the polyurethane topcoats on the forebeam |

So Baw and Sue scootered off towards Phuket town to the huge TOA paint store and were happy to learn that for $1.30 they will tint the Interthane 990 linear polyurethane, by computer. But the color match still had to be done by eye, so it was good to have Baw there to help determine the best TOA color chip match to Ocelot White, which is an off‑white with undertones of brown and pink. They found a match, the man punched it in, and now the spars will be very closely matched to the gelcoat, and they should all come out the same! We even got a sticker so we should be able to match future batches even more easily.

At the yard, Jon helped Baw and Heru determine the mixing ratios for the paint and thinner. They did it by weight which was far easier than by volume given the numbers we wanted to work with. Baw sprayed for half an hour and got about 5 pots of 300 grams (1.5kg total) of top coat on the forebeam. It looks great.

Akoosh & Yando polishing while AME checks stainless fit |

AME showed up for final fitting of our stainless steel protectors - one on each bow and 3 pieces on each stern (the swim‑ladder breaks them up). They had the starboard bow piece all polished up and it looks good. After everything was fitting nicely, they took everything back to AME to send off to the electro‑polishers. Since they had their truck, we gave them the new stainless from Luck as well - the 4 new hand‑rails, the cockpit backrest, and both swim‑ladders with their hinges.

Jon got some good sanding time in on the rudders. Unfortunately, we put glass on the tops of the rudders, and then wrapped the sides in more (and much heavier) glass - which moved the glass on top, creating air bubbles under the top glass. After futzing with it for a while, Jon decided to remove both pieces of glass from the tops of both rudders and just redo the tops. He cut away the old glass, sanded the tops of the rudders smooth, and cut more 200g cloth to replace the top pieces. If the good weather holds, he hopes to get them epoxied on tomorrow.

Jon checking the fit of the 3-part stainless stern protectors |

Jon also worked on the salon window. He used a fiber wheel (like a wire wheel, but the "wires" are a tough fiber) to remove the last vestiges of silicone from the aluminum window frame. It seems we'll still have to cut and dig with the tools for the majority of the silicone, but then the last bits will "grind" out without hurting the anodized aluminum. Baw offered, once again, to repair the acetone‑damaged acrylic window. But then he said he was too busy during the day, so he would take it home to do. We are curious how it will turn out. There's no doubt it would be a great time and cost savings if he could repair the acrylic, but we don't want to look out through wavy windows. We Shall See...

Sue seemed to spend the day on the scooter. First to town with Baw for the paint tinting. Then after lunch she scootered up to Boat Lagoon. She investigated light fixtures at AME and found a very close equivalent of the inset lights we had originally. Before we order any we will dig very carefully through our storage boxes for the old ones. A couple hours searching is worth possibly saving $1000 in lights. Her other Boat Lagoon errand was to buy the Awl Grip aluminum primer, Max Cor. It's hard to believe that 1.5 liters is supposed to cover our remaining 30 square meters of spars, but we are forever optimistic and (hopefully not naively) trusting of the spec sheets on the stuff. If they lie as badly as OceanMaster, we'll have to reconsider...

Pla sanding the bimini, preparing it for a final gelcoat spray |

The other big job today was that we started preparing for the final gelcoat spray on the bimini. We moved the bimini out from under Ocelot and as far forward as we could. Then Pla and Heru started sanding the areas around the nonskid, preparing them for gelcoat, while Baw built a wall of plastic between the bimini and Ocelot.

This shouldn't be a big spray. The bottom of the bimini was sprayed and polished months ago, and the top had the "gutters" sprayed months back as well. So all that's really needed is a bit of gelcoat along the edges of the nonskid, and a bit up forward where we had to sand some off. Jon measured the area to be sprayed at 4.2 square meters, but much of that's already good gelcoat, and Baw's concerned that we won't have enough gelcoat for other areas that need spraying. Weather permitting, Baw would like to spray tomorrow.

Whole lotta clampin' goin' on, attaching the trim in the salon |

Houa got Ben to help him with his teak trim gluing project, which must have been nice for Ben. Something different from sanding, sanding, and more sanding. Together they got the whole forward salon seat trim area sanded, and the long teak piece glued and clamped in place. They also got the 2 side pieces installed. Tomorrow the last 2 pieces go in. Houa also got the panel of teak strips assembled and cut to fit the starboard salon shelf to cover the water‑damaged veneer.

Lek stripped the varnish from the galley "sill", cleaned up the teak and got the first layer of epoxy on all the exposed teak in the galley. This includes trim under the sinks, around the new stove, and the floor "sill". He also got a second epoxy coat on the teak under the nav‑table.

Lek sanding under the nav-desk for another coat of epoxy |

The starboard sugar‑scoop got within a couple square feet of completion. Akoosh and Yando were on it all day, using 2000 grit sandpaper. Chambron was absent, and perhaps he is our primo gelcoat sander. If we ever let Baw have a free minute he may get around to polishing the sugar‑scoops.

Tuesday, October 15:

A hot sunny Tuesday, with a couple brief drizzles just to cool things off. But we got some

good things done, despite being short‑handed. Today is the very special Islam holiday,

Eid‑al‑Adha, locally known as Hari Raya, so our 4 Indonesian

workers were not at work. Eid Mubarak to them and their families!

Bo cleaned our starboard engine room all day |

Actually the day began with a new worker, Bo, a young Thai woman who arrived at 8:15 ready to clean. So we set her up in the starboard engine room with bucket, rags, Scotch Brite pads and detergent. She spent the entire day in there (minus lunch, of course) and really got things looking clean. We especially asked her to wipe down each and every tube and pipe and fitting so that we could see what needs to be repaired or replaced.

Today is one of Baw's 2 hospital days this week, so we knew we only had him for half a day. But boy, what a great half day. The men moved the forebeam from its spray tent and placed it on cushions under Ocelot. Tomorrow the boom will move into the tent and get sanded, and maybe oxalic acid wiped, in preparation for spraying with primer.

Removing the painted forebeam from the paint tent |

The main thrust of the morning, though, was the gelcoating of the bimini edges and around the nonskid. Since it was already in its plastic half‑tent, and Pla had sanded it yesterday, it only needed a good acetone wipe today. Jon and Baw checked the quantities of gelcoat left: 5kg from Mike at AME (without wax, as it was for making our nonskid in the mold) and 5.5kg left of our own. What a shock to open the containers and see very different colors of white! So we stirred them up well, and the colors got closer. We decided to mix the two, to average out the color, and to spread the wax from one into the other.

Today's spray covers 4 square meters but Mike sprayed most of that months ago. The only place more gelcoat is really needed is up against the edges of the 4 big sheets of nonskid, and over a small strip at the front of the bimini where some bad gelcoat was sanded back to bare glass. So we decided to only spray on 3kg of gelcoat, to which we added 0.7% mono‑wax to offset the increased monostyrene Baw needs to thin the gelcoat for his 1.8mm gun.

Spraying the bimini "gutters" between the sheets of nonskid |

Baw sprayed from 11:30 until just after noon and now we have a beautiful white bimini! Woot! After lunch the gelcoat was already cured enough to remove the masking, so Jon and Pla did that and also trimmed off the excess gelcoat above the edge of the nonskid, a job that took 10 minutes with the gelcoat newly soft but would have taken hours if we'd waited until it was fully hard. It should be easy to sand and polish in the next couple days, with the gelcoat fresh. Then we can hoist it up on deck and fasten the back to the targa‑bar so the front legs can be designed and built.

After lunch Lek returned to his salon teak project. In the morning (when not helping with the gelcoat spray) he sanded under the nav‑desk and around the galley trim as well. In the afternoon he brushed on epoxy coat number 3 under the nav‑desk and number 2 in the galley.

Using a fiber wheel to dig silicone out of the window frame |

We had an amazing revelation today. Baw has been saying that he can polish our side window acrylic that was badly damaged by acetone to bring it back as good as it was, but we haven't believed that he could sand the acrylic back to optical flatness. So last night he took the pane that we'd removed home, along with some super‑fine sandpaper. He worked on it for 4 hours and brought it to us this morning. We can't see where he worked on it, and there's no distortion when looking through it. Amazing! Now we wish we'd listened to him and let him polish the window in situ, before we'd removed it. But at least he should be able to fix the other damaged window as well, saving us the time and expense of replacing both windows.

Sue used Houa's clever tools on the window frame, getting rid of the worst of the silicone on the sides and top and all of it from the corners. Jon resumed his work with the fiber wheel, which makes a mess, but really gets the aluminum cleaned off. The final job will be to wipe with a commercial product called "Silicone Off" that softens the silicone and removes the last of its residue.

Houa did all the messy, dusty stuff in the salon in the morning so as not to get in the way of Lek's wet epoxy after lunch. He scraped and peeled and cut off the blue tape from under the salon seat trim so now he only needs to install the last 2 straight pieces. On the starboard salon shelf he scraped back and then sanded away the last of the damaged veneer. Down in his workshop he finalized the teak strips that will replace that veneer. He's making it from solid 5mm teak instead of veneer, to make it more resistant to water damage. Houa got it all glued together and shaped so Lek could give it a final sanding and apply the first protective coat of epoxy in the late afternoon . Tomorrow it will be sanded and epoxied again before being glued to the shelf.

One rudder finished, the other getting its fiberglass on top |

Jon and Sue worked together in the afternoon on the last of the rudder project. We had thought we were done last week, but the glass strips on the very top of each rudder had bunched up and gotten air pockets underneath, so Jon took them off yesterday. Today he hand sanded the rudder tops through wet epoxy to block the oxidation of the stainless steel. Then he put on 2 sheets of specially cut 200g fiberglass cloth. He also smeared a fillet of epoxy filler in a hollow on the trailing edge of each rudder and rolled a sealing coat of epoxy on both rudders. Tomorrow he'll trim off the extra fiberglass and sand the rudders for a coat of Interseal 670 primer to protect the epoxy from UV. Then the rudders can finally be reinstalled!

Chambron folded up, sanding the port fo'c's'le bilge for painting |

Wednesday, October 16:

Dare we say it, another good day? Touch wood. Things are still moving forward, sometimes

quite quickly.

All the workers were back except Akoosh, so we had 5 different areas of work going on. Sue continued to play manager, photographer, gopher, and troubleshooter. She even got time to get more silicone off the salon window using rags, tools and Silicone Off, which is only useful for the last thin film of silicone residue. And she cleaned out a big storage box of engine goodies, scrubbing away grease, fiberglass dust, oil and grunge.

Heru, Chambron, Ben and Yando were on the bimini all day (though not all of them all the time). They got all the gutters sanded with 400 grit, which is the normal point of doing any necessary gelcoat repairs, but Baw reported there were no repairs necessary. So they got it all marked up again and got about 1/3 done with 600 grit. It should move along faster now, with the finer sandpapers.

Houa and Ben positioning the long teak aft-deck toe-rail |

Ben spent some time in the morning up on the aft deck sanding and polishing the strip of gelcoat that goes under Houa's long teak toe‑rail. The teak has tunnels in it for the water to drain aft and out, and Houa wanted to be sure the gelcoat in these tunnel floors was well polished so they'll be easy to clean. Now that the sanding is done, Houa can start mounting his long teak strip.

Today Houa finished a lot of the salon projects. He replaced a small strip of damaged veneer under the rounded cabinets, got the 5mm teak strips glued to the starboard shelf, and routed the edges of the salon seat trim so that it rounds off nicely. Lek will be doing a final sanding on that and brushing on epoxy and polyurethane. Houa's last little salon project is to cut and mount the solid teak aft border of the new 5mm strips, separating the aft shelf from the newly repaired part in front. We will then be matching on port and starboard. What a concept!

Houa epoxying in the last 2 pieces of seat trim in the salon |

Bo (our new woman worker) continued to clean deep into the starboard engine room. It's all spiffy looking up above the aluminum floor, but today she dove aft into the dusty fiberglass area under the steps. Houa seems to have taken on being our interpreter for her, so that's good for both us and her. Once the cleaning is done, we'll be hopping down in the engine room ourselves to see just what needs repairing, painting, changing, etc. At the very least, the base of the rudder tubes need to be painted, where they were reinforced.

Lek worked on his epoxy and teak projects in the salon. The area under the nav‑desk now has 4 coats of epoxy, and the galley got its third today. Tomorrow he'll probably move up to the starboard shelf where Houa built the raised sections to repair old veneer.

Baw and Pla polishing the boom before giving it an acid wash |

Pla and Baw were a 2‑man team today. They used grinders with wool polishing pads to buff up the boom. Unfortunately Sue had not gotten all the Nyalic off, so when they hit it, it burned and stank. But a few minutes with Xylene and rags and it was taken care of. After the grinding was done they mixed up a solution of oxalic acid and brushed it on, then rinsed with fresh drinking water (the hose water is from a local well and full of green stuff and contaminants for the aluminum). They got the boom moved to a better location and built a big tent around it, using some of the tent that had housed the forebeam. If they get the tent finished in time tomorrow, Baw may be able to spray on the new anti‑corrosion primer. Fingers crossed.

Jon spent a long time sanding the rudders thoroughly, making them as smooth as possible. After lunch he declared them ready for primer so we commandeered Heru from the bimini project to help. Jon used the scale to weight out 570g of part A and 100g of part B, then Baw insisted we add some thinner, even though we were gong to be rolling it on. So Jon was pouring thinner into the pot and then Baw said "Poa, poa." Well, to us it sounded like "pour" so Jon kept poa'ing. Finally Baw said clearly, "Stop Mr. Jon!" Who'd have thought Baw would speak Thai to us in that situation? And that the word "Poa" means stop! Well, it's a good way to learn a new Thai word.

Heru and Jon painting the 2 rudders with an epoxy primer |

We had a rather thin batch of Interseal 670 epoxy paint and a good laugh. So Jon mixed up a bit more paint, without thinner, and then thinned it with the ultra thin mixture. He and Heru got several good layers rolled onto the rudders and they are now bright and white and ready for anti‑fouling some day before we launch.

Knowing we were going to mix Interseal, we asked Baw to get one of the men to jump down port engine room and sand the new fiberglass over the whale damage repair that was never painted. Surprisingly, he asked Chambron, our tall, leggy Indonesian. Not that he isn't a good worker, but that he is (like Jon and Sue) so tall it is uncomfortable to squat down in the engine room. But he did a thorough job of sanding, vacuuming, and acetone wiping and Heru got a couple coats rolled on there. Then, because we had some extra paint already mixed, we had Chambron jump down the fo'c's'les to prepare the deepest aft bilge where the transducers go. Starboard was easy as it already had 670 primer on, so it just needed a bit of roughing up and some acetone. Port took longer, and he used the dancing (orbital) sander, because that bilge and the foc's'le sides had never been primed that far back. Anyway, he got it all prepared, and Heru got more white primer rolled on.

Ben and our brightly dressed Indonesians polishing the bimini |

With the extra paint we made a contribution to the painting of the concrete toilets in front of Ocelot. The interior wall of one stall is now Interseal 670 white.

Thursday, October 17:

Sunny and hot. And so much going on today it's hard to remember it all. Thank goodness

we take pictures. We seem to be at the point where "projects" are short and sweet, not

month‑long extravaganzas. We can hope.

Baw spraying etch-primer on our boom. It's turning Green! |

The major accomplishment of the day was that we got new green primer (AwlGrip MaxCor) sprayed on the boom and a bracket. Baw and Pla worked quickly to finish the tent, then with Heru they set up the compressor and paint station. The only gotcha was that Pla suddenly (just before painting) pointed to the boom rollers and said "Blue tape?" Uh, yeah, and we needed blue tape on the spinlocks as well. Sue did her little going nuts thing to be sure they didn't touch the boom with bare hands after it had been acetoned. We think the men think they don't have body oil or fingerprints. Maybe we should find some way to show them, at a non‑critical time.

The spray itself went quite well, with the MaxCor going on beautifully (not at all like the OceanMaster). After the boom spray we turned into a beehive of activity. Baw spent about an hour sanding the second acetone‑damaged window on portside salon. Pla set about finding and fixing little gelcoat blemishes. He used a drill bit held in a vise grip to "sand" the inside of the little holes, then dabbed in gelcoat. This hardens really fast, and can be sanded smooth within a couple hours.

Polishing out the white on the window, which is all raised up 1mm |

We asked Baw to get someone to sand and prepare the port fo'c's'le for a coat of Interseal 670 primer. When we first put on the primer months ago, we weren't sure if it was what we wanted, or if it would be hard enough to withstand the scraping and clunking of things in the fo'c's'les. So starboard had been fully primed, but not port. Yesterday we got the deep bilges of each side done (mainly so we could fit the transducers) but on port there were still walls and the main shelf to do, where we had stopped before. Before we knew it, Chambron had been down in the port fo'c's'le with the orbital sander, sanded the walls and floor, and cleaned up with acetone. First we knew of it was when Heru appeared with a small bucket of 2‑part epoxy primer, all ready to paint. It was really gratifying. Later in the day Heru got a second coat on, so now we have 2 very white fo'c's'les. We may put on a 2‑part enamel top coat, at least deep in the bilges where there is often water. But so far, so good.

Heru polishing the anchor support that goes out to the forebeam |

Jon checked the rudders but the paint wasn't fully cured - not too surprising given that too much thinners was in some of the paint. We want them both hard so we can sand the paint smooth before installing them. Maybe Friday?

Heru set up the grinder and wooly wheel to begin the pre‑primer sanding of the prod. He hung it up in the spray‑tent when he'd finished, then moved on to the anchor support, which is a complicated thing and tricky to move the grinder wheel around without snagging it. It had never received Nyalic, so it had never been polished smooth.

Akoosh was back, so we had 3 Indonesians and Ben on the bimini all day. It didn't go as fast was we'd hoped, but they did stop all sanding to do little dit‑dot gelcoat repairs. By day's end they were up to 1500 grit, so tomorrow should see the polishing. We can hope - which means we need to plan how to hoist it up on deck...

Jon fixing his gaskets behind the 2 engine instrument panels |

Sue ran errands, took pictures, took the final silicone off the salon window, and did a lot of cleanup of fiberglass dust from around the helm station (inside) on the wires and instrument panels.. She also dug in the store room for engine manuals and helm instruments. All that because Jon's big push of the day was to mount some of the helm instruments. The hole for the throttle and gear controls has been completely glassed over and needs to be re‑cut, so Jon made a cute template of the mounting surface. But the engine instruments should probably be mounted first, followed by the sailing instruments, before the engine controls, as the thick cables for the engine controls get in the way of everything else.

But when Jon unwrapped the Yanmar instrument panels from the plastic bag that had been their home for the last 2 years, he found the rubber mounting gaskets were badly perished. Some clever shopping at local aluminum and window shops produced a couple versions of rubber gasket, neither of them perfect but both probably usable. Jon chose one, went back to that store, and the man happily GAVE him 10' (3m) of it, for free. After a bit of cutting and fiddling and gluing (yay superglue) he had 2 custom‑made gaskets. Jon and Sue gingerly unwound all the control‑panel wires (both panels are still connected) and threaded the panels out their mounting holes so Jon could fit his new gaskets. By late afternoon they were positioned and ready to install. Awesome. We are beginning to look like a boat.

Houa preparing to mount the teak aft-deck toe-rail |

Lek spent the day hand sanding the new salon seat trim, then cleaning up and getting the first coat of epoxy on the teak. This will no doubt be followed by 1‑2 more coats before polyurethane varnish.

Houa was also in and out of the salon. He inserted small teak plugs in some random holes in the salon seat. He finished making and then gluing the solid teak trim piece that separates the old salon side shelf from his newly raised one. Outside on the aft‑deck, he spent time fitting and marking the placement of the long teak toe rail. It will have to be planed down a few millimeters at one end to accommodate the upswing of the gelcoated deck, but it's looking great. He plans to get it Sika'd into place tomorrow.

Baw spraying white mid-coat on the boom |

Friday, October 18:

A long, hot day with good things happening. But not for Jon. Thai Tummy struck, and sent

him home early. Not fun.

First big job of the day was to get the white Interseal 670 primer sprayed on top of the Awlgrip MaxCor etch‑primer on the boom. Baw wanted to give the MaxCor a light sanding, but Sue fell back on the spec sheet which implied that no sanding was necessary if over‑coated within 7‑72 hours. So we called Toi, owner of Yacht Supply, who sold us the MaxCor. She and Baw had an animated conversation in Thai, and the upshot was that he did a light sanding. She also said we could overcoat MaxCor after only 2 hours, which directly contradicts the published specs. Hmm... Who to believe? So Baw and Pla gave the green boom a light sanding, then Baw shot on a kilo of white primer (actually, a mid‑coat).

Houa gunning toe-rail Sikaflex while Heru prepares the louvers |

Baw then retreated from the heat and fumes to polish the second (and still installed) acetone‑damaged window. We don't know if it's finished now or not, but it's unfortunately a bit wavy, which was what we were concerned about. Tomorrow will tell.

Houa spent the day on the teak toe‑rail for the aft deck, planing it to fit and sanding the teak itself and the gelcoat on which it sits. He got the long rail stuck down with brown Sikaflex, the same stuff that is holding the teak deck in place in the cockpit. Because the aft deck and its gelcoat are not completely flat, he had to use various clamps and wedges to get the teak positioned just right, and then clamped down correctly. It'll be nice to see it once the excess brown Sikaflex is cut away.

Our Indonesians got the bimini sanded up to 2000 |

Pla spent the rest of the day sanding down the little dit‑dot gelcoat repairs he made to the starboard sugar‑scoops yesterday.

Sue cleaned up 3 old propellers, got most of the silicone off the removed acrylic window, and spent time in Phuket town doing our 90‑day check‑in with immigration. Her afternoon project involved meeting with Chai, an awing and upholstery guy who came recommended by our friends on Migration. So we walked him through all the possible cushion/covering/mattress needs and we hope to get a quote soon.

Chambron, Yando and Akoosh spent the day perched on the bimini, with either pencils or sandpaper in hand. We were happy that they were going to finish sanding the top all the way through 2000 grit, but then they pointed out that the bimini edge under the bolt‑rope holders had not been sanded above 800. It didn't seem like that much more to do.

Baw spraying gelcoat around the nonskid on the louvers |

So, given that the men were all teasing about needing cool drinks (the soda lady was nowhere to be seen and it was over 95°F/38°C) Sue offered cool drinks IF the men finished the whole bimini. Chambron brightened up and said, "Yes, Madam. Cool drink. Big energy!" So, 9 iced tea and Schweppes lemon tonics later (not all for the 3 bimini guys!) we had a finished bimini! Tomorrow is polishing day!

Baw apparently got a lot of energy from his lemon tonic as well, because after lunch he and Heru had begun to prepare the 4 louvers for their second gelcoat spray (the one around the nonskid). They sanded the existing gelcoat and masked the nonskid. The next thing we knew they had moved them out from under Ocelot, set up the compressor and got them sprayed! Way cool.

Lek sanding the big shelf on the starboard side of the salon |

One thing not way cool is that we are running very low on gelcoat. Last weighing in we did, we had 10.5kg, and have now used 3kg on the bimini and 2kg on the louvers. We still have touch‑up patches to do on the bow, the deck, the engine hatches, and the helm seat. It's going to be very close.

Lek got the salon seat trim sanded and ready for another coat of epoxy. Then he spent time meticulously sanding the outer starboard shelf. This is veneer, and he has to be careful not to go thorough it. But there were water stains to be sanded out, so it needed work. By day's end he had cleaned it all up and was ready for epoxy tomorrow.

Our woman worker, Bo, was once again ensconced in the port engine room. With luck it will be done tomorrow, and we can use her help elsewhere. Or maybe she'll be moving forward to actually clean the engine itself which means working from inside the boat, leaning down on top of it from an aft bed. Not fun (although this is the position Jon has to use when working on the engines). Good thing she's young and agile.

Pla and Heru sanding the mid-coat on the boom |

Saturday, October 19:

A busy, slightly cooler day to end the week, with heavy dawn showers and more rain at

6pm, but nothing in between. All the workers were back (it's payday, after all) but Jon was

still out recuperating.

Although we were ready for the bimini to be polished, Baw postponed it in preference to working on things that will move us along and keep the men working. After the polishing, the bimini will be raised to the deck, but then it's mostly a Jon‑only job. So Baw, Heru and Pla worked on the boom all day, sanding the white Interseal 670 mid‑coat. The boom itself is pretty smooth, but there are a few dents and corrosion places. These got filled with yellow 2‑part body filler which will be sanded out and hidden under the final linear polyurethane top coat.

Removing the old varnish from the fixed "doors" |

Lek worked in the salon again. The possibility of rain made us all leery of epoxy work, but by 9am it was clearly going to be an okay day for resin. So Lek got a third coat on the salon seat trim and a first coat on the outer starboard shelf. Then he sanded the epoxy under the nav‑desk in anticipation of polyurethane varnish.

In the afternoon he began removing the old varnish from 2 of the "doors" on the peninsula. These "doors" are actually permanently mounted, as we had to remove that cabinet when we expanded the fridge/freezer in 2001, and we used the old doors to form the wall. But the problem is that the rounded doors at the end of the peninsula are new teak with epoxy and polyurethane top‑coats, which produces a darker look than our original teak, which has now gone a nice honey color. To prevent a zebra‑esque alternating dark, light, light, dark, dark, light, dark look, we've decided to strip back the 3 lighter teak panels and make everything the same color. By removing the old varnish we can best emulate new teak and the panels will all be closer to the rich warm red of new teak.

Akoosh, Yando, Ben, and Chambron sanding the louver gelcoat |

Ben, Chambron, Yando and Akoosh spent the day communing with the louvers. Before removing the vinyl masking they sprayed on a light coating of black spray paint. This helps them see where they have and have not sanded. With the vinyl off, Chambron carefully cut away the excess gelcoat from the nonskid borders. Then all the men wet sanded all day. They finished 320, 600, and 800 grit on all 4 louvers. Tomorrow they'll do 1500 and 2000, then polishing.

Sue ran errands, as usual, including a trip all the way past the apartment to Home Pro for the (surprisingly) cheapest blue tape around. It was pay day, so there was the inevitable bank run. Our payroll is currently about $200/day or $1200/week. She finished getting the last of the silicone off the extracted salon window, so it's ready to be cleaned and returned to its aluminum frame. After talking with Baw about the wavy condition of the other port window (the one he polished in situ) it seems that it's really hard to get a smooth finish on a vertical window. So we will probably remove the wavy one and let Baw do his magic on a horizontal surface.

The 2 "eyebrows" in their initial locations |

Bo worked in the port engine room again, but her progress is glacial. Not sure what her next project will be, if any. We hired her brother once and found him too idle. A low energy family?

Baw and Sue toured the inside of Ocelot to see what jobs still need doing. It's a bit of a long list, but it all seems very do‑able with our big crew of good workers. Baw is looking forward to getting the full list of what was discussed so he can distribute the men. In a nutshell, there are bilges to be cleaned and others to be painted. There is wood to be sanded in preparation of polyurethane varnish, and the floors to be sanded and sprayed with Epiphanes polyurethane (as opposed to the cheaper but lower quality local TOA product) for strength. There's sanding and varnish to apply in the salon itself and the galley, and gelcoat in some bilges to be cleaned and sanded to brighten it.

Houa got the brown Sika 298 cut away from the toe‑rail, so now it looks great. After lunch he began the fitting and checking and sanding and cutting of the 2 eyebrows (rain catchers) over the companionway and the galley window. There was some choice of how long to make them, and how to position them. They're basically finished except for positioning but Houa and Sue couldn't make the decision, so Houa ended up screwing the eyebrows to the cockpit "wall" and leaving them there for Jon's approval or comments on Monday.

Thai Refit:

Ocelot Pages:

Top Level: Home | Destinations | Cruising Info | Underwater | Boat Guests | Ocelot | Sue | Jon | Amanda | Chris | Site Map | Make a Comment

|

If our information is useful, you can help by making a donation |

Copyright © 2000‑ Contact: Jon and Sue Hacking -- HackingFamily.com, svOcelot.com. All rights reserved.